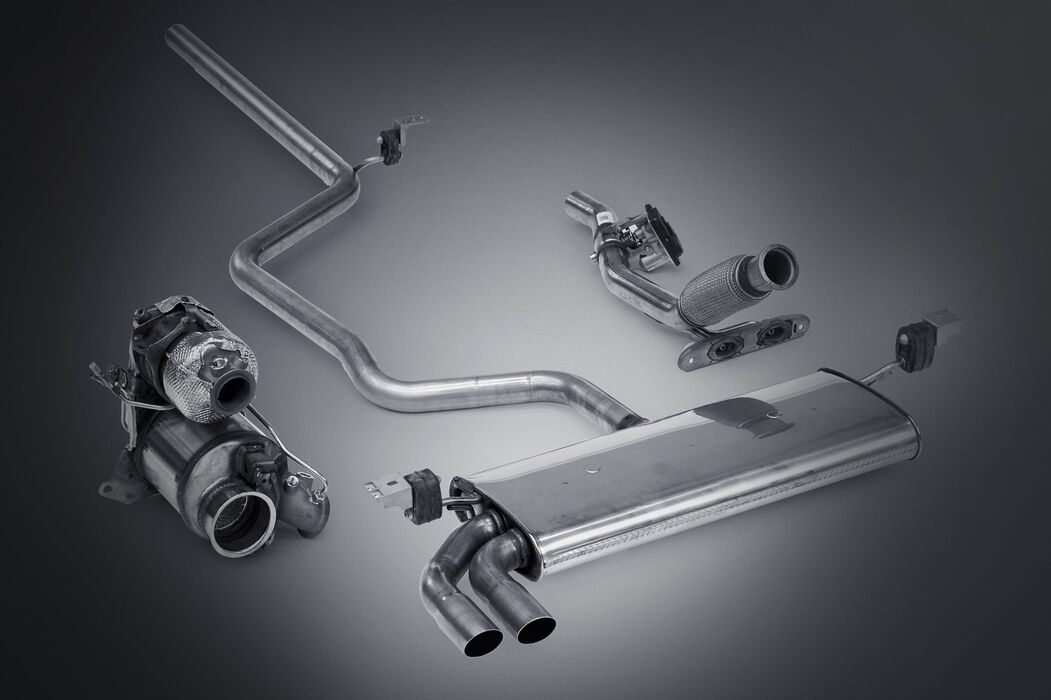

Double-walled precision and complex shapes

In the exhaust system, lightweight construction is subject to the toughest of tests. The fischer group has demonstrated again and again how precise air gap insulated double wall constructions can be manufactured that can withstand environmental conditions at any time. The precisely fitting exhaust damper housing is one of the best examples of this.

DHowever, even the most complex designs, such as hydroformed manifold parts or common connectors such as ball head, Torca and V-board connectors, document the range of components made from fischer tubes already successfully in use.

Tail pipes, funnels and Y-tubes show the extreme reshaping of high-temperature-resistant parts that can be realized.

Robust structural parts with hydroforming

Hydroforming has also opened up new horizons in the area of structural parts for automotive applications. Whether crossmembers or longitudinal beams, you benefit from the unlimited range of hydroforming shapes, with which a variety of secondary shaped elements can also be integrated. This results in individually developed chassis structural components that are optimized for both strength and weight.

On various presses with up to 12,000 tonnes and a table size of up to 2.8 x 6 meters, the fischer group offers plenty of possibilities even for larger structural components.

Lightweight construction and economy combined

Components close to the engine mainly include exhaust gas recirculation cooler housings. Here the fischer group has shown how lightweight construction can be implemented economically with small subassemblies, from inner winglet tubes to housings with a variety of shapings and prefabrications.

In thin-walled stainless steel, even visually appealing, heat-resistant charge air pre-tubes ensure a first-class look in the engine compartment with low weight.

Constructive safety built in

Tank systems must reliably store and transport fuel at all times. At the same time, they must provide adequate ventilation – while meeting the highest safety requirements. Even in an emergency, the sensitive area must not pose any danger. For this purpose, fischer tubes with and without metal bellows have proven to be extremely reliable. This applies to flexible or rigid filler necks as well as to flexible tank ventilation tubes.

For this purpose, the fischer group has produced pre-assembled multi-part components as tank inlets or filler necks. Another contribution to process efficiency in later final assembly.

High-precision thermal management

With electric drives the right cooling plays a decisive role. In the coolant circuits, movable and static parts must be hermetically sealed from each other. The fischer group's stator and rotor sleeves perform precisely here.

With often only 0.2 to 0.3 mm wall thickness, the sleeve families for coolant pumps are extremely thin-walled. Their diameters usually range between 20 and 50 mm.

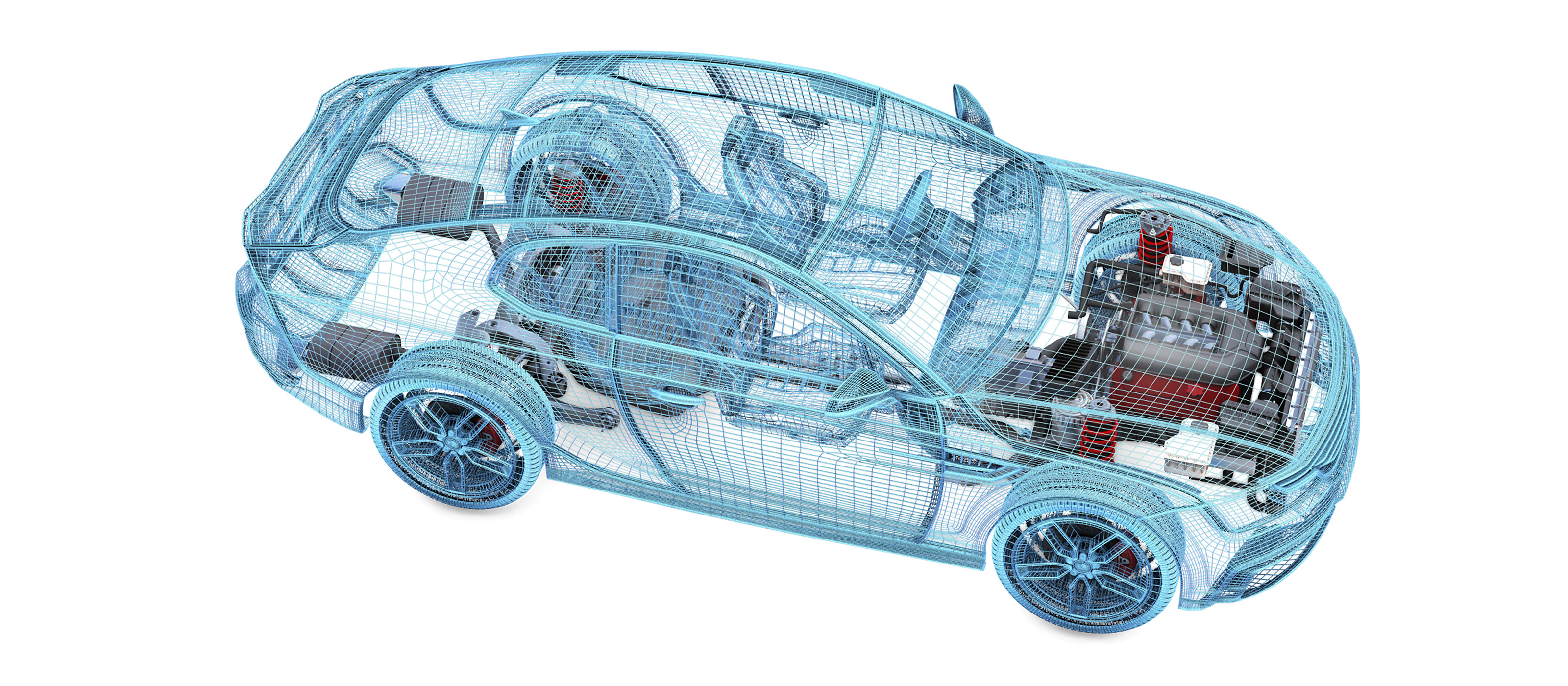

Your global automotive partner

The fischer group is represented worldwide at the most important hotspots in the automotive industry. Millions of vehicles use fischer's highly corrosion-resistant tubing, components or subassemblies. From development to worldwide production, we're close to you: the fischer group turns innovative ideas for the future of the automobile into complex shapes. From stable exhaust manifold components to complex subassemblies – fischer stainless steel tubing ensures reliable mobility.

Corrosion-free and space-saving

In the automotive industry more and more technology has to be accommodated in the smallest of spaces. Especially in the field of exhaust technology, it is important to develop intelligent designs that also meet the high physical demands of mechanical stress, heat and corrosive influences. The fischer group offers convincing solutions for this.

Joint developments

From your first ideas to prototypes and individual solutions to serial production, at the fischer group you will always find competent contact persons who understand and advance your processes and value creation parameters.

Typical applications for fischer tubing and components in automotive manufacturing

- Exhaust systems

- Exhaust tail pipes

- Outer shells for catalytic converters and diesel particulate filters

- Filter housings

- Housings for exhaust gas coolers

- Fuel rails

- Chassis structural components

- Soundproofing

- Safety components (e.g. for airbags)

- Tank filler necks

Quality by conviction

The fischer group lives up to extraordinary quality standards in all areas of the company. Internationally recognized quality management systems and certifications are an expression of this fundamental conviction.

Your contact person for Automotive