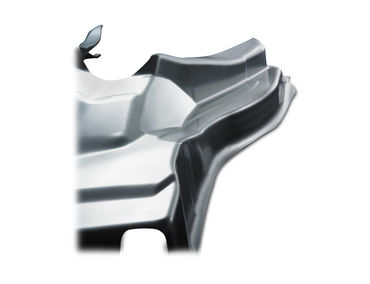

Aluminum structural parts for automotive and aerospace

With the HFQ® technology (Hot Form Quench), the fischer group is able to produce previously unknown lightweight components with the same high strength. Aluminum hotforming provides new freedom in the design and use of complex yet lightweight components made from high quality aluminum-copper alloys (2XXX), aluminum-magnesium-silicon alloys (6XXX) and aluminum-zinc alloys (7XXX).

Versatile in use

The scope of application of the new method ranges, for example, from structural bodywork components in vehicle manufacturing for both conventional and alternative powertrains to components in aviation. Typical aluminum subassemblies in passenger seats of aircraft construction or rail transport can be realized more cheaply. The technology allows the material aluminum to further penetrate many other areas of application such as space travel, consumer electronics or architecture.