For top physical properties

Annealing results in microstructural homogenization in the tubes. This makes them more malleable and increases corrosion resistance. The treatment is necessary for complex further processing, e.g. in chemical plant building or hydroforming. The fischer group offers heat treatment in line during tube production or as a separate process. In a high-grade inert gas atmosphere discoloration is prevented and the corrosion resistance of the surfaces is maintained.

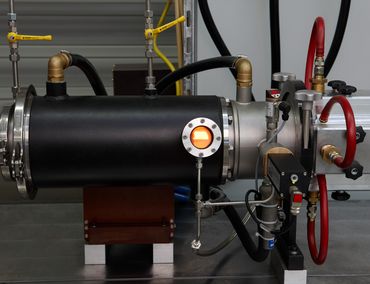

With inline annealing the tubes are bright annealed in inert gas at 300–1,200°C. Continuous production is possible here.

In a continuous process tubes up to 6 m in length are annealed in inert gas at 600–1,120°C.