Laser Blanking as-a-service directly from the coil: Economical and high-precision blank manufacturing

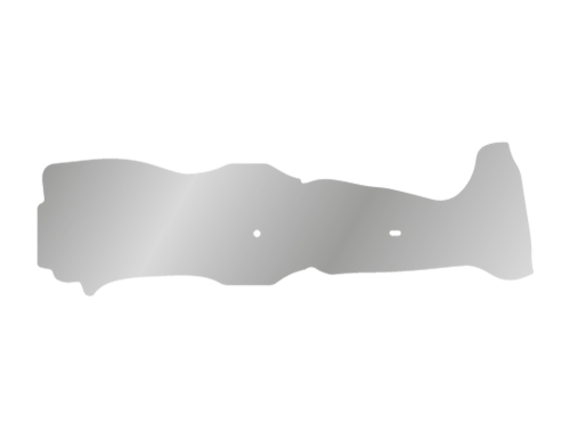

Tool-free laser cutting has long been the manufacturing process of choice for the efficient production of sheet metal blanks in small to medium batch sizes. Only laser cutting offers the flexibility to efficiently and precisely produce different contours and materials in rapid succession.

Connecting laser blanking to a coil and straightening line opens up even more cost-effective opportunities. Blank production is now possible directly and without detours from the coil: This enables even better nesting and material utilization as well as faster production overall.

E-mobility in particular offers a large field of application: With laser blanking, semi-finished products for EV body parts, battery housings and modules or other alternative drive concepts can be manufactured quickly and efficiently from prototype development to series production. Coil laser blanking thus opens the door for flexible but at the same time sustainable production of semi-finished sheet metal products.

Benefit from this innovative technology for your projects.

- Blank production directly from coil

- Optimum material utilization and minimum scrap rates

- All common metallic materials

- Working area of the laser cell: 4000 mm x 2150 mm

- Coil weights of up to 20 tons

- Coil widths from 400 mm to 2150 m

- Cutting and positioning tolerances of less than 0.05 mm

- Precise cutting of wall thicknesses up to 4.0 mm